cold riveting

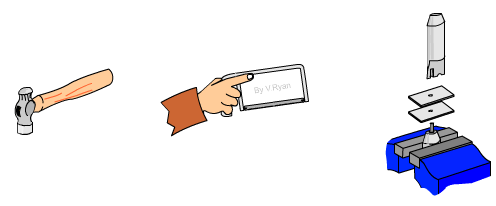

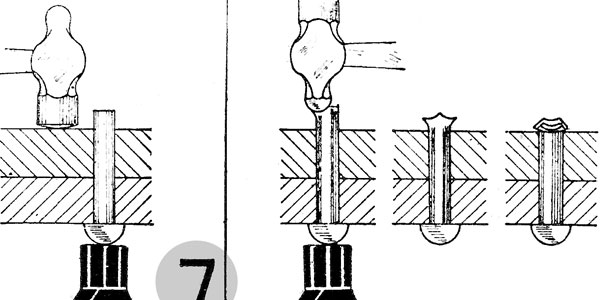

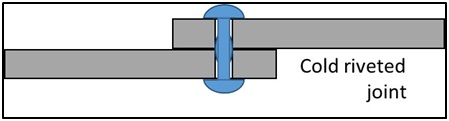

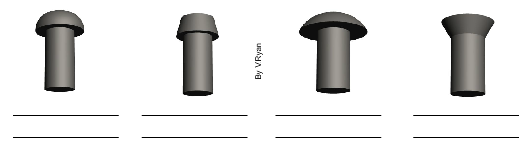

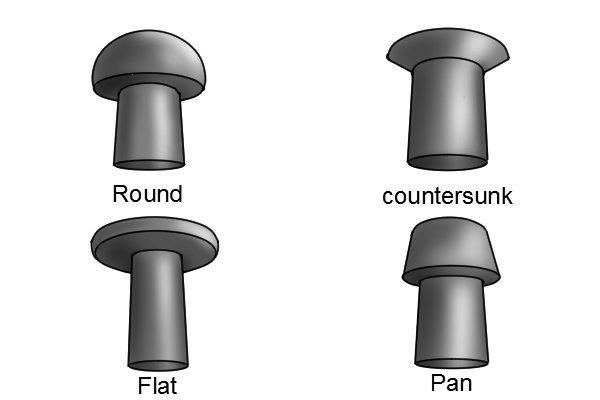

- Attention! google_ad_client = "pub-16980376316045"; google_ad_width = 728; google_ad_height = 90; google_ad_format = "728x90_as"; google_ad_type = "text_image"; google_ad_channel ="; google_color_border = "336699"; google_color_bg = "FFFF"; google_color_link = "0000FF"; google_color_text = "000000"; google_color_url = "008000"; //... Victims of colors, pixels and used media, pixels and USOSV. Ryan. 2004 - 2018 FILLO PDF - The rice pads are used to join dishes together and have has been used for hundreds of years. Before the widespread use of welding, The rivets were used in heavy industries such as shipbuilding. Steel plates used to build ships like the Titanic and the naval Dreadnaughts of World War One was held together by steel rivets. Rice has been largely replaced by techniques such as welding and brag. However, joining plates along with rivets remains useful technique especially if the plates to join are quite small. Cold rivets are still used in school workshops, although modern The pop-riveting technique is more popular. SNAP HEAD PANEL HEAD MUSHROOM COUNTERSUNK (adsbygoogle = window.adsbygoogle TENTED []).push({}); Below are two steel plates that have joined permanently using stainless steel rivets 'big head'. Plates can't move a part because the rivets keep them firm. The rivets shown above are the main types and heads of each shape variable. Cabezal rivets have been selected for the work shown below because matter that the heads show on the surface of the metal. QUESTION: What kind of rivet would be chosen if the head of each rivet should be level with the surfaces of the Cantaes? FILLO PDF - 1. Below is a range of cold rivets. Name of each type. 2. The diagram below shows two steel plates with four holes pierced through each plate. Sketch each of the rivets up in position, through the holes. Your drawings should show how each rivet You'll take care of the process of riveting. One of the rivets He's already been drawn for you. 3. The tools/equipment below are used during the process Riveting. Tag/name of each of the tools. 4. In the space below are explained how this type have been used in the past and how they are used by modern Manufacturing. (adsbygoogle = window.adsbygoogle TENTED []).push({}); The rice pads are used to join dishes together and have has been used for hundreds of years. Before the widespread use of welding, The rivets were used in heavy industries such as shipbuilding. Steel plates used to build ships like the Titanic and the naval Dreadnaughts of World War One was held together by steel rivets. Rice has been largely replaced by techniques such as welding and brag. However, joining plates along with rivets remains useful technique especially if the plates to join are quite small. Cold rivets are still used in school workshops, although modern The pop-riveting technique is more popular. SNAP HEAD PANEL HEAD MUSHROOM COUNTERSUNK Below are two steel plates that have joined permanently using stainless steel rivets 'big head'. Plates can't move a part because the rivets keep them firm. The rivets shown above are the main types and heads of each shape variable. Cabezal rivets have been selected for the work shown below because matter that the heads show on the surface of the metal. QUESTION: QUESTION: What type of rivet would be chosen if the head of each rivet should be level with the surfaces of the Cantaes? FILLO PDF - PDF FILE2. The diagram below shows two steel plates with four holes pierced through each plate. Sketch each of the rivets up in position, through the holes. Your drawings should show how each rivet You'll take care of the process of riveting. One of the rivets It has already been drawn for you.4. In the space described below, explain how this type have been used in the past and how they are used by modern Manufacturing. Web www.technologystudent.com Web www.technologystudent.com - Attention! google_ad_client = "pub-16980376316045"; google_ad_width = 468; google_ad_height = 15; google_ad_format = "468x15_0ads_al_s"; google_ad_channel ="; google_color_border = "336699"; google_color_bg = "FFFF"; google_color_link = "CC0000"; google_color_url = "008000"; google_color_text = "000000"; //...

cold riveting – Mechanicalinfo

Cold Rivets - Types and Uses

Cold Riveting Process - DesaignHandbags

Force to squeeze rivet - Metal and Metallurgy engineering - Eng-Tips

Difference Between Hot Riveting and Cold Riveting

Difference between Cold Riveting and Hot Riveting - Advantages and Limitations | Mecholic

ME3263 Design for Manufacturing and Assembly

About Making and the Use of Rivets – Small Farmer's Journal

Rivets vs. Bolts

Cold Rivets - Types and Uses

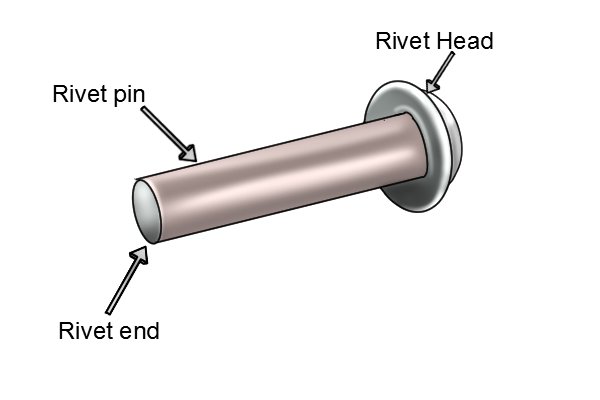

What are the parts of a solid rivet? - Wonkee Donkee Tools

RoyMech - Rivets

Hydraulic riveting machine for cold riveting - YouTube

Cold Rivets - Types and Uses

Improved shear strength design of cold-formed steel connection with single self-piercing rivet - ScienceDirect

6 Hot Tips for Cold Connections: Master Riveting, Metal Tools, and More | Interweave

METHODS OF RIVETING - China Saijin Electrical Alloy

Riveting & Cold Connections For Jewellery Making

Riveting Archives - difference.minaprem.com

5 Riveting Details: When, Where, and How to Use Rivets and Other Cold Connections | Interweave | Riveting, Rivets, Soldering jewelry

Rivet - Wikipedia

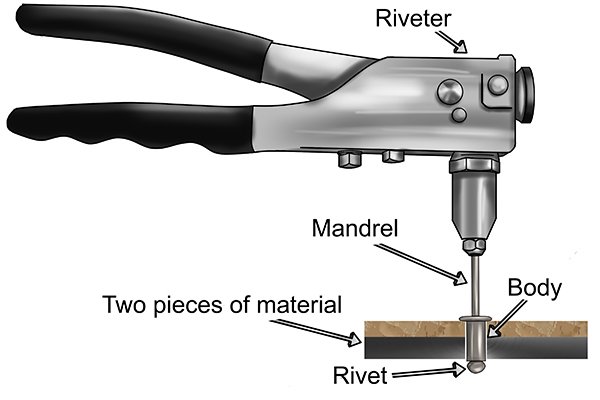

How does a blind rivet work? - Wonkee Donkee Tools

China Cold Riveting Machine for Truck Crossbeam, Lifting Lug - China Electric Hydraulic Riveting Machine, Cold Riveting Machine

Riveting @ titogy86 :: 痞客邦 ::

Types of riveted joints - Types of failure in riveted joints

History of Rivets & 20 Facts You Might Not Know | Goebel Fasteners

China Ym Series Hydraulic Cold Riveting Machine - China Riveting Machine, Hydraulic Cold Riveting machine

Radial and Orbital Riveting Add Finesse to Fastening, Joining | Machine Design

The Forgotten Art Of Riveted Structures | Hackaday

Electric Hydraulic Cold Riveting Machine - Buy Riveting Machine,Cold Riveting Machine,Chassis Riveting Machine Product on Alibaba.com

Rivets and Lockbolts | Engineering Library

Bonding and riveting Dec 2014

Figure 6 from Joining of Cold-Reduced Carbon Steel Sheet and Aluminum Sheet by Impulsive Riveting Method and Punch Riveting Method | Semantic Scholar

What are the different types of solid rivet? - Wonkee Donkee Tools

3 Most Common Riveting Issues Demystified | Interweave

Solid Shank Rivet (Aircraft Structural Fasteners) | Aircraft Systems

Hot & Cold Riveting at Chassis Alignment - YouTube

Hydraulic Cold Riveting Machine YM series_Zaozhuang Make Machinery co.,Ltd

Desktop Crm Cold Riveting Machine Eyelet Riveting Machine For File Folders - Buy Eyelet Riveting Machine For File Folders,Desktop Riveting Machine,Crm Cold Riveting Machine Product on Alibaba.com

Rivets – Types, Failures Of Riveted Joint, Terms Used In Riveting

Posting Komentar untuk "cold riveting"